Flexographic Printing Machine

Flexographic printing machine uses fluid ink, which is more liquid.

Ink from the ink roller and reticulate ink roller to the printed version of the graphic part and make it ink. Then the impression cylinder press , let the printing plate of the ink transfer to the substrate. Finally, finish printing through the dry surface.

The printing section is the core of the flexographic printing machine. Printed part of the arrangement directly affect the operating performance and printing quality. Printing speed and printing of the scope of application is also affected by the printed part. According to the arrangement of printing parts, flexographic can be divided into three categories. They are satellite flexographic printing machine, unit-typed flexographic printing machine and stack flexographic machine.

Stack Flexographic Printing Machine

Stack flexographic printing machine sometimes is also called accumulated flexographic printing machine. There are independent printing unit up and down, arranges at one or both ends of the main wall panel of the printing machine. Or install various colors printing units on the rack.

Each printing unit is rotated by a gear mounted on the main wall panel. Stack flexographic printing machine can print 1-8 colors, but is usually 6 colors.

Satellite Flexographic Printing Machine

Satellite flexographic printing machine sometimes becomes a common impression roller flexographic printing machine. Each printing unit move around a common impression cylinder, which is installed in between the two panels. The printing material is printed around a common impression cylinder. Because the gears are directly driven, it is possible to print on paper or film, even if no special controls are attached. The printing process is stable and is often used to print color products.

Unit-typed Flexographic Printing Machine

Unit-typed flexographic printing machine consists of a line connecting type flexographic printing machine, which is composed of 4-8 independent and horizontally arranged and driven by a common power shaft.

-

Two/Four/Six Colors Satellite Flexographic Printing Machine 710021

Satellite flexographic printing machine can be adapted to a range of paper, up to 150 meters per minute.The printing machine can help customers increase productivity, and get more profit. The new satellite flexographic printing machine adopts the center roller embossing, chromatic high precision. It has high accuracy, and improve the printing quality. Satellite flexographic printing machine has a wide range of applications. The machine can be printing a variety of materials. It can print two/four/six colors of the material.

Learn More -

Industrial High Efficiency Non Woven Bag Machine 710075

Process Flow Of Non Woven Bag Machine : Load material (non-woven membrane) → folding → ultrasonic bonding → cutting → bag (blunt) → waste recycling → counting → stacking.

Non woven bag machine has advanced design technology and fast production speed. It also has high efficiency, which can process different specifications and shapes of non-woven bags. The quality is good, and the bonding strength is high.

Learn More -

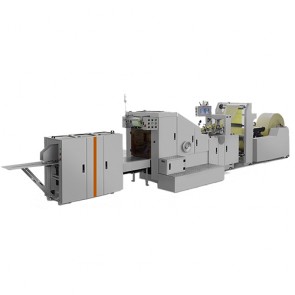

High Speed&Efficiency Square Paper Bag Machine 710077

- The square paper bag machine uses servo motor and color tracker. It can accurately tracking the printed materials.

Learn More

- Motion controller integrates with the fiber to achieve high-speed and high-precision motion control.

- Square paper bag machine uses touch-screen display, which operational functions is clear understanding. It has a better human-machine interface.

- The machine adopts cold spray glue system. The glue quantity can automatically adjust with the speed of mechanical operation.

- The machine is equipped with a block alarm. The plug will automatically alarm when it block. It can avoid damage to the machine due to the jamming. -

High Speed Two/Four Colors Stack Flexographic Machine 710030

Satellite flexographic printing machine can be adapted to a range of paper, up to 150 meters per minute.The printing machine can help customers increase productivity, and get more profit. The new satellite flexographic printing machine adopts the center roller embossing, chromatic high precision. It has high accuracy, and improve the printing quality. Satellite flexographic printing machine has a wide range of applications. The machine can be printing a variety of materials. It can print two/four/six colors of the material.

Learn More -

High Speed Six Color Stack Flexographic Machine 710039

- It is easy to operate the six color stack flexographic machine, starting soft, chromatic accurate.

Learn More

- According to the customer's printing quantity, the meter counter can be set as required. The six color stack flexographic machine will automatically shut down when it reach the quantity set. The printing machine will also automatically stop without materials.

- Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

- Anilox roller ink transfer, ink evenly.

- Reliable drying system, with high speed operation. The six color stack flexographic machine will automatically shut down when short-circuit.

- Frequency control, in order to adapt to different printing speed.